Articles

- Intel

- Samsung

- Texas Instruments

- STMicroelectronics

- Infineon

- NXP Semiconductors

- Microchip

- Analog Devices

- onsemi

- Skyworks Solutions

- Avago

- Marvell

- Omnivision Technologies

- ROHM

- Seoul Semiconductor

- Silego

- Cirrus Logic

- Silicon Labs

- Lattice Semiconductor

- Cypress Semiconductor

- Toshiba

- Mitsubishi

- Panasonic

- Sharp

- Omnetics

- Laird

- TDK-Lambda

- WAGO

- All Distributors

Siemens Unveils AI-Enhanced Electronic Systems Design Software

Siemens has unveiled upgrades and AI enhancements to its flagship electronics design suite. The suite integrates updated tools and multidisciplinary project lifecycle management (PLM) with cloud-based collaboration and enhanced security. While printed circuit board (PCB) design remains at the core of the suite, the new version spans the entire design process and takes full advantage of cloud computing and artificial intelligence (AI).

Siemens End-to-End Design Suite

Siemens claims that the system was developed with a deep understanding of individual designer needs as well as broader industry trends. Large engineering design projects today must account for external factors such as workforce transitions, long-term supply chain instability, and both the positive and negative uncertainties brought about by AI. Siemens has taken these factors into account in the updated tools.

Overview of the Upgrades

The system consists of six core modules centered around three flagship products. Xpedition and PADS have long been known as premium electronic design software, while Valor has been a leader in design for manufacturing (DFM) solutions for many years. The new release integrates the latest versions of these three packages into a unified design flow that covers all key project needs. The included packages are:

· Xpedition: PCB and electronic systems design software for enterprise teams

· Innovator 3D IC: IC packaging and planning tool for integrating ASIC and chiplet chips

· HyperLynx: A set of PCB analysis and verification tools

· PADS Professional: PCB design for smaller teams

· Valor: DFM software for moving PCB designs to the manufacturing floor

· PartQuest: Cloud-connected supply chain and bill of materials (BOM) management system

Siemens also offers connectors to additional modules, such as TeamCenter NX product lifecycle management (PLM) software, SimCenter, and other third-party software solutions. The suite also bridges the gap between electronic design and mechanical computer-aided design (MCAD), improving collaboration and reducing team and logistics overhead.

Design Suite Capabilities

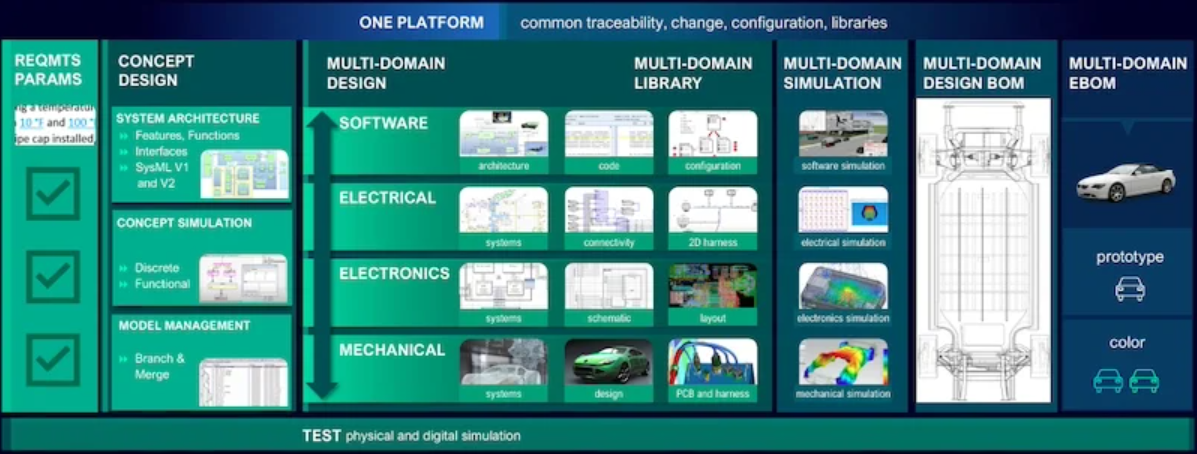

Circuit design has evolved into a much more holistic process. Manufacturability must be considered from the outset, and DFM now covers a broader range of factors than it used to. Design teams must consider a range of issues before making the first move with their design, including regulatory concerns, cybersecurity, uncertainties around part availability, and new innovations.

Siemens Design Platform addresses end-to-end complete development flow.

Siemens’ design platform addresses the entire development flow, enabling integration across disciplines. For example, a mechanical designer working on the product package might identify a physical constraint, such as a required bolt hole. When the MCAD designer sets the constraint, the PCB layout operator immediately sees it and can adjust the design accordingly. The system allows for seamless information transfer across the entire design flow, even when dealing with multiple PCBs or custom chip pin layouts.

Artificial Intelligence Enhancements

AI is used within the design suite to assist users rather than replace them. One key area where AI is leveraged is in PCB routing. The newly enhanced Xpedition and PADS PCB design software utilize AI to suggest routing paths and guide the designer through the process. Even when manually routing, AI anticipates potential issues, helping to avoid poor design outcomes and providing real-time guidance.

Siemens also uses AI to improve the user experience within the software suite itself. One of the biggest challenges with upgraded software is ensuring a smooth transition from older workflows. The new suite anticipates user needs, allowing the software to guide the user to the next step, minimizing time spent navigating menus or recalling new processes. Predictive AI has improved the user experience with minimal retraining and disruption to the design process.

Leveraging the Cloud

Complex projects require powerful tools and multiple collaborators, often located in different regions, sometimes across the globe. The cloud is the only practical solution for supporting this kind of distributed workflow, and Siemens has adopted this approach for its design suite. Cloud connections also enable collaboration with design and PLM software from other vendors.

Cloud-based operations enhance workflow efficiency for distributed, multidisciplinary teams.

Security is a major concern when working with dispersed teams and cloud-based software. In addition to the usual risks of cyber-attacks, intellectual property theft and exposure to malicious actors are significant threats. To address these risks, the design suite includes robust controls that prevent unauthorized access to sensitive data, even in unapproved locations or environments. The software uses geofencing and location-based security, in addition to standard user-based security measures. These controls ensure better security and compliance with military and aerospace standards.

All images courtesy of Siemens.

Previous: Onsemi Launches Modular Analog and Mixed-Signal SoC Platform

Next: AMD First to Launch FPGA Devices Featuring CXL 3.1 and PCIe Gen6