Articles

- Intel

- Samsung

- Texas Instruments

- STMicroelectronics

- Infineon

- NXP Semiconductors

- Microchip

- Analog Devices

- onsemi

- Skyworks Solutions

- Avago

- Marvell

- Omnivision Technologies

- ROHM

- Seoul Semiconductor

- Silego

- Cirrus Logic

- Silicon Labs

- Lattice Semiconductor

- Cypress Semiconductor

- Toshiba

- Mitsubishi

- Panasonic

- Sharp

- Omnetics

- Laird

- TDK-Lambda

- WAGO

- All Distributors

Onsemi Launches Modular Analog and Mixed-Signal SoC Platform

Onsemi has introduced its advanced Treo platform, a modular analog and mixed-signal system that integrates multiple functions—including power management, sensor interfaces, and communication subsystems—into a single, modular architecture. The platform is designed to meet the high-performance demands of automotive, medical, industrial, and AI data center applications.

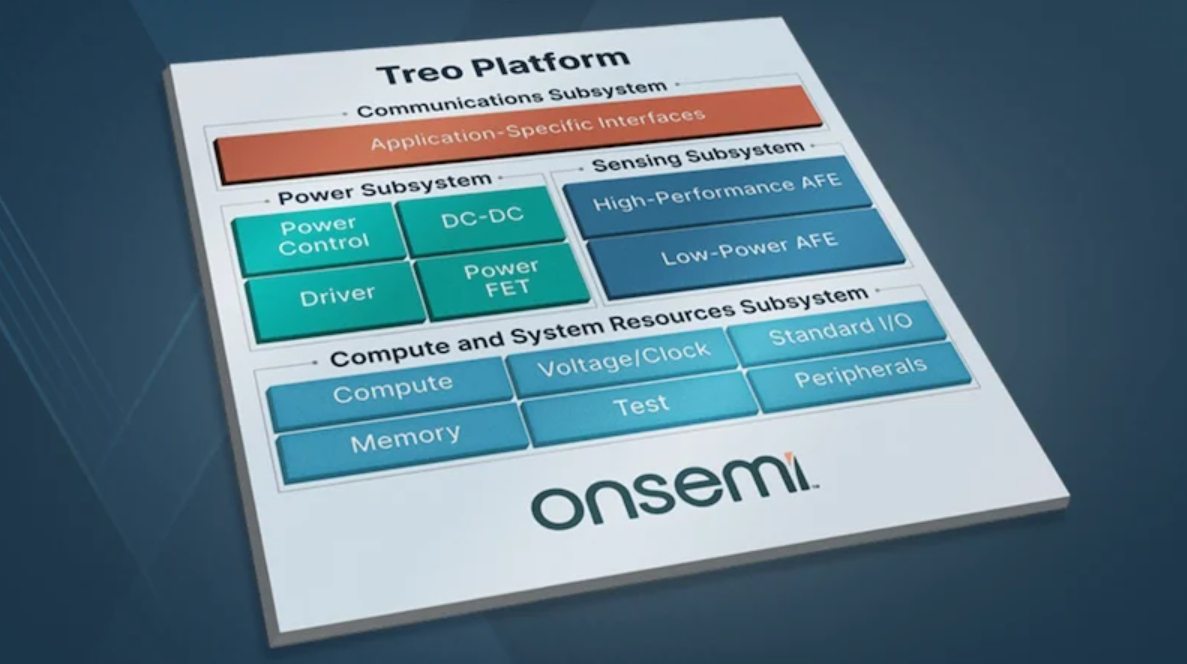

High-Level Block Diagram of the Treo Platform

All About Circuits interviewed Vijay Rentala, Vice President and CTO of Onsemi's Analog and Mixed-Signal Group, to learn more about the platform's features.

Advanced 65nm BCD Process

A key feature of Treo's architecture is its 65nm Bipolar-CMOS-DMOS (BCD) process, which combines the benefits of bipolar transistors, CMOS, and DMOS on a single chip. Each component offers distinct advantages: bipolar transistors provide high analog precision for sensitive signal processing, CMOS enables efficient digital processing and complex control logic, and DMOS transistors handle high-voltage and power requirements.

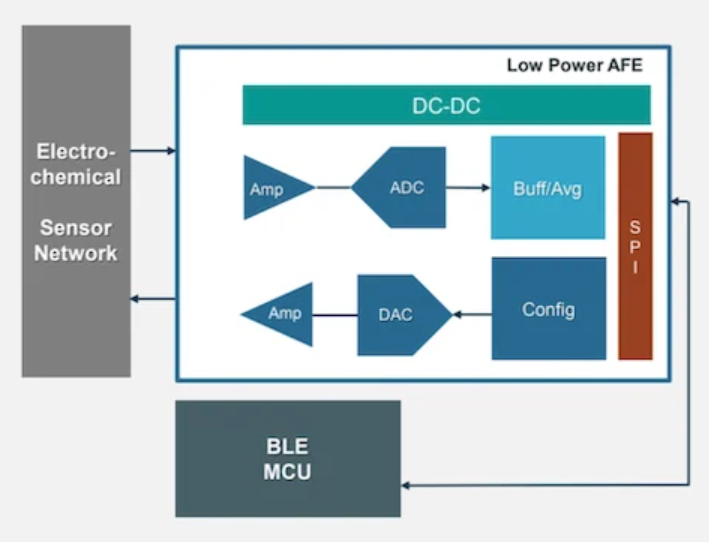

One application use case of Treo: an ultra-low-power analog front end (AFE) in a continuous glucose monitor.

Operating at 65nm gives Treo a unique position among analog and mixed-signal platforms. While previous BCD technologies have typically been limited to 90nm or larger nodes, the reduction to 65nm increases integration density and reduces the chip footprint. According to Rentala, this process density consolidates multiple functions into a single die, reducing silicon area without compromising performance or reliability.

“65nm enables high-density digital, high-performance analog, and high-voltage power all in a single modular technology,” he explained.

In addition to the compute subsystem that provides digital control, the power management subsystem includes features like DC-DC converters and low-dropout regulators (LDOs). The sensing subsystem includes analog front ends (AFEs), and the communication subsystem supports technologies like single-pair Ethernet.

Expanded Voltage Range and Noise Isolation

Treo supports a wide voltage range of 1V to 90V, a significant contrast to many competing platforms that use segmented voltage domains within narrower ranges. These systems often require separate processes or discrete components to manage the various voltage requirements. Treo’s ability to handle voltages from 1V to 90V at temperatures up to 175°C on a single platform simplifies the design process by integrating both low- and high-voltage circuits on a single chip.

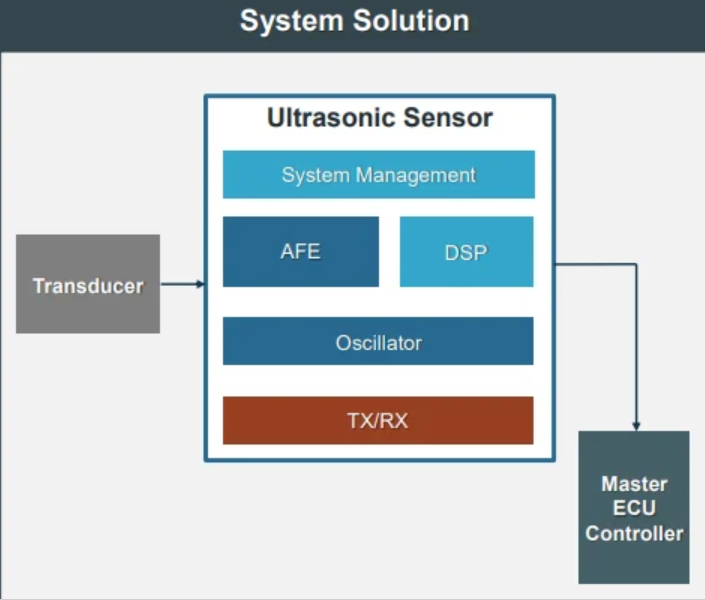

An ultrasonic sensor ADAS solution using Treo.

For example, in automotive systems, the shift toward 48V power architectures in electric and hybrid vehicles requires components that can handle both higher voltages for power delivery and lower voltages for control circuitry. Treo’s broad voltage range, combined with its high integration density, offers manufacturers a streamlined path to build power management units (PMUs) that can support multi-level voltage requirements without adding complexity to the system design. This results in reduced bill-of-materials (BOM) costs and shorter time-to-market.

Treo also leverages Onsemi’s proprietary noise isolation techniques.

“We developed unique solutions for isolating noise from sensitive analog circuits and placing a high-performance analog circuit next to a high-voltage power device without causing interference,” Rentala said.

According to Onsemi, Treo’s design isolates high-voltage power stages from sensitive analog circuits to prevent noise interference without requiring external filtering components. This feature is particularly beneficial for applications like automotive, where sensitive circuitry must operate in noisy and harsh environments.

Future Plans for Treo

Onsemi plans to expand the Treo product family by 2025 to include additional solutions in high-performance sensing, DC-DC conversion, LED driving, and connectivity.

“With this technology, we are providing unique value to our customers, enabling them to develop system solutions that were simply not possible before,” Rentala concluded. “The modularity and flexibility open doors to design possibilities across automotive, industrial, and medical applications.”

All images used courtesy of Onsemi.