Articles

- Intel

- Samsung

- Texas Instruments

- STMicroelectronics

- Infineon

- NXP Semiconductors

- Microchip

- Analog Devices

- onsemi

- Skyworks Solutions

- Avago

- Marvell

- Omnivision Technologies

- ROHM

- Seoul Semiconductor

- Silego

- Cirrus Logic

- Silicon Labs

- Lattice Semiconductor

- Cypress Semiconductor

- Toshiba

- Mitsubishi

- Panasonic

- Sharp

- Omnetics

- Laird

- TDK-Lambda

- WAGO

- All Distributors

A Comprehensive Overview of Winbond's Memory Technology for Edge AI

AI computing is recognized as one of the most critical technological areas in semiconductor memory.

For AI edge computing, Winbond offers a memory technology called Customized Ultra-Bandwidth Elements (CUBE), designed to enable high-performance, optimized generative AI processing for hybrid edge/cloud applications.

In this article, we will take a deep dive into this technology and explore how it addresses the challenges engineers face when developing edge AI computing systems.

High-Bandwidth Memory Needs for Generative AI

Generative AI—and AI in general—relies on the power of large models to process intricate patterns and relationships within their respective domains. This drives up the demand for computing resources, including both processing and memory.

To support AI applications, memory chips and modules must provide sufficient performance across multiple parameters. Bandwidth is only part of the equation—power efficiency, form factor, and thermal management are equally critical in edge AI designs.

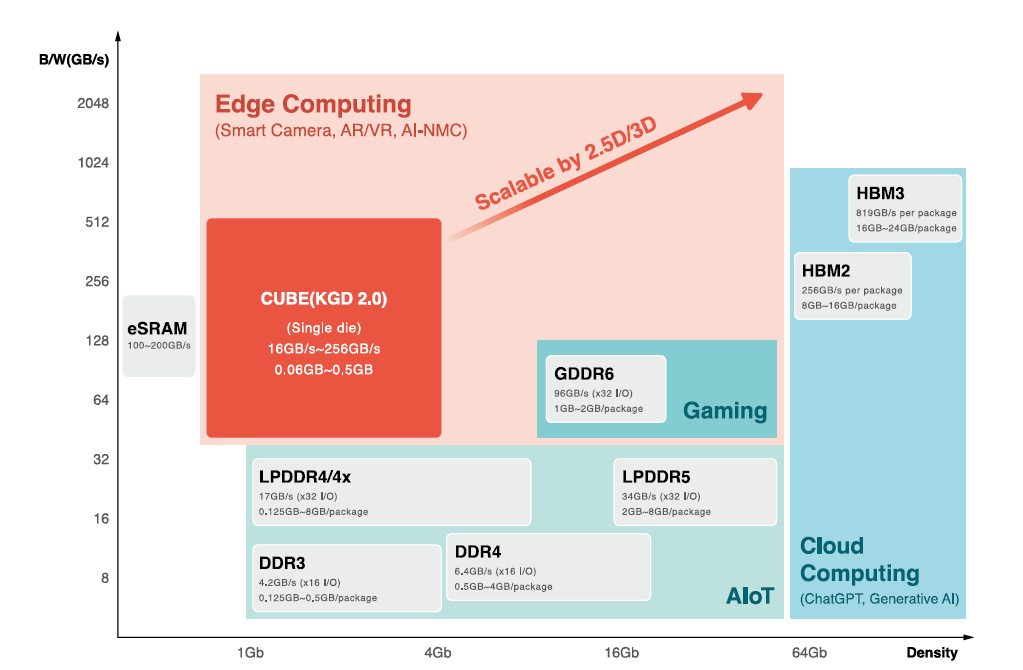

Bandwidth vs. Density: The Scalability Advantage of CUBE for Edge Computing

Existing memory solutions face bandwidth limitations that affect overall performance. Physical factors, such as the number of IC pins, data transfer rates, and the width of the memory bus, all play significant roles in determining interface bandwidth.

Increasing memory bandwidth presents significant challenges. As speeds increase, signal integrity becomes more difficult to maintain due to issues like attenuation, crosstalk, and reflections, which impede bandwidth scaling. Moreover, higher bandwidth often leads to increased power consumption and thermal management issues. These problems are particularly pronounced in compact, battery-powered edge devices.

How CUBE Overcomes the Limitations of Conventional Memory ICs

To address these challenges, Winbond’s CUBE technology incorporates the following three key innovations:

1. Novel methods for increasing I/O count and boosting data transfer speeds

2. Support for Through-Silicon Via (TSV) technology as an optional feature

3. A 3D architecture that reduces thermal dissipation issues

CUBE enhances the performance of front-end 3D structures, such as Chip-on-Wafer (CoW) and Wafer-on-Wafer (WoW), as well as back-end 2.5D/3D chip-on-silicon interposer and fan-out solutions.

CUBE’s I/O interface supports a data rate of 2 Gbps with 1K I/O, providing bandwidth ranging from 16 GB/s to 256 GB/s per die. This ensures accelerated performance that exceeds industry standards while enhancing power and signal integrity through micro-bump or hybrid bonding technologies.

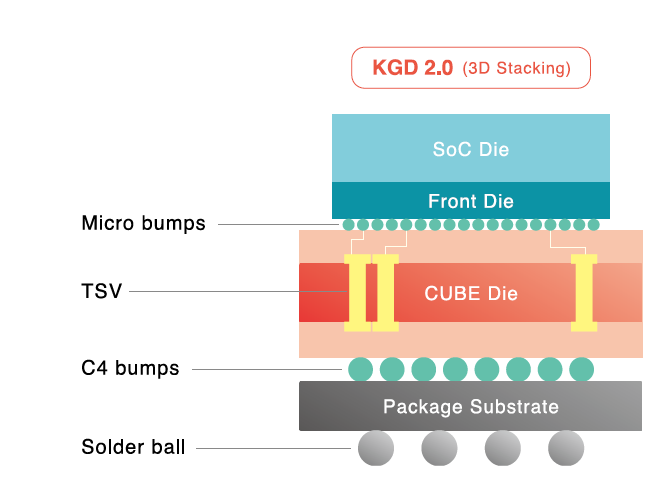

CUBE 3D Stacking

CUBE offers configurations from 1 to 8 Gb/die based on the D20 specification, providing flexible design and 3D stacking options to accommodate smaller form factors. Through-silicon vias (TSVs) further improve performance by enhancing signal integrity, power integrity, and heat dissipation.

TSV Enhances Performance and Reduces Costs

By using TSV technology in conjunction with micro-bump or hybrid bonding, designers can reduce power consumption and save area in the SoC design. Efficient 3D stacking, leveraging TSVs, facilitates integration with advanced packaging technologies. By reducing die size, CUBE lowers device costs while improving energy efficiency due to shorter power paths.

The combination of increased bandwidth, energy efficiency, improved response times, and support for customization and compact die sizes makes CUBE well-suited to unlock the full potential of edge AI, as well as hybrid edge/cloud use cases.

Winbond actively collaborates with partners, including IP design houses, foundries, and OSATs, to bring CUBE technology to system designers.

A Scalable Path for Edge AI Designs

Today's demanding edge AI applications require a scalable roadmap for next-generation system designs. Technologies like Winbond’s CUBE memory represent a crucial tool for this forward-looking path. To learn more, be sure to visit Winbond’s website. And if you're in Munich, Germany this week, visit Winbond at booth A5-153 at the Electronica 2024 trade fair.

All images used courtesy of Winbond

Previous: AMD First to Launch FPGA Devices Featuring CXL 3.1 and PCIe Gen6

Next: What Are MRDIMMs? The Memory Technology Servers Designers Are Discussing